Introduction

In 1999, when the first edition of this NEDCC Preservation Leaflet was published, the use of fire sprinklers in cultural heritage properties, which includes libraries, archives, museums and historic structures, was often met with reluctance over fears that the activation of a sprinkler could result in greater damage than the fire. However, as time has passed and experience has demonstrated that the proper design and installation of these systems can save the properties from catastrophe, sprinklers have become widely accepted. For example, it is now widely viewed among fire safety professionals that had the attic of the Cathedral of Notre Dame been fitted with sprinklers, the April 2019 fire would have been a short duration and readily recoverable event, rather than one of the most expensive fires in a cultural heritage property.

During the past twenty years, significant advancements have occurred in fire detection, emergency notification, and automatic sprinkler equipment as well as in understanding how these systems can be more effectively used to safeguard our heritage. Fire detection systems can identify developing fires at the earliest moments, long before they become dangerous, and they do so with greater resistance to false alarms. Voice-type fire alarm notification is now clearer in quality and, in some instances, able to guide the building’s occupants to a point of safety. Fire sprinkler improvements have included more capable sprinkler components with better materials and the ability to reach previously difficult spaces, and greater acceptance and use of low water flow mist sprinklers. In addition to these technological advancements, there has been a greater emphasis on performance-based engineering where fire systems are specifically selected and designed for a property’s unique features.

The basic premise of the 1999 Leaflet still remains true: The stakeholders of a cultural heritage property have the responsibility for safeguarding these unique and often irreplaceable structures and collections from losses that may be incurred due to any number of hostile events including vandalism, environmental and natural factors, and fires. Of these, the speed and totality of a fire’s destructive forces place it among the greatest and most significant threats, with consequences that may include:

- Collections damage. Most heritage institutions house unique and irreplaceable objects that fire-generated heat and smoke can severely damage or totally destroy beyond repair.

- Operations and mission disruption. Heritage occupancies can contain educational facilities, conservation laboratories, catalogue services, administrative and support functions, exhibition production, retail, food service and an array of other activities. A fire can interrupt or shut down any of these functions with adverse impact on the organization’s mission and stakeholders.

- Structure damage. Buildings provide the “shell’ that safeguards collections, operations, and occupants from weather, pollution, vandalism and numerous other environmental factors. A fire can destroy walls, ceilings, floors, roof assemblies, and structural support, thereby exposing contents to the elements. Fire can also disrupt climate control, electrical and communication systems, and lighting. This may result in damage to collections as well as extensive and/or expensive relocation and temporary housing arrangements.

- Physical harm to the institution’s staff and visitors.

- Adverse public relations. Staff and visitors expect safe conditions in cultural heritage facilities. Those who donate or loan collections items presume that these will be safeguarded. A significant fire could alter public confidence and result in negative publicity.

- Security impact. Fire can be one of the most significant threats to an institution’s physical security. Given the same amount of time, a fire can cause greater security disruption than a vandal or professional thief.

To minimize fire risk and its impact, heritage institutions must develop and implement comprehensive and objective fire protection programs that include fire prevention, early fire detection and alarm notification, limitations on internal fire spread, and efficient fire extinguishment. Fire protection for cultural heritage properties can be more complex than that required for the average business property, and subsequently there is not a single set of answers or solutions that are applicable for all situations. The primary question that needs to be asked by the institution’s stakeholders is, “Are we doing everything possible to prevent a fire, and if a fire does happen, what do we want to remain when it is extinguished?” The remainder of this document focuses on the various fire detection and suppression options that are now available for these special and unique properties. Additional helpful information and guidance for safeguarding these facilities is found in the National Fire Protection Association (NFPA) #909 Code for the Protection of Cultural Resource Properties - Museums, Libraries, and Places of Worship, and NFPA #914 Code for the Protection of Historic Structures, available from www.nfpa.org.

Fire Detection and Notification

A key aspect of fire protection is to identify a developing fire emergency in a timely manner and then alert the building's occupants and the fire department. This is the role of fire detection and alarm systems, and depending on the anticipated fire scenarios, building characteristics and use type, number and type of occupants, and criticality of contents and mission, these systems can provide an array of functions from general alarm to extremely early identification of minute quantities of smoke. They can identify a developing fire through either manual or automatic methods, they will alert the building’s occupants to commence evacuation, and they will signal the fire department to respond. These systems may also shut down electrical circuits or air handling equipment, close fire doors, and in some instances, serve to initiate fire extinguishing systems.

Fire alarm systems consist of the following components:

- Fire Alarm Control Panel (FACP) Conventional Style – The FACP is a control unit that monitors the status of each detection device (smoke sensor, thermal sensor, manual alarm pull station, fire suppression system) and provides the alarm notification. “Conventional” is an older style where one or more detection circuits radiate from the FACP to the various devices, and when one of the devices activates, the system recognizes the zone and provides an alarm. These systems are only capable of identifying the zone that is in alarm and not the specific device. In large or complex buildings, this may result in large areas that need to be inspected before the exact location of the fire can be determined, and valuable response time may be used and the fire may gain intensity before the location is identified. Conventional systems were a common fire alarm choice in the past but are now rarely used for full building systems.

- Fire Alarm Control Panel (FACP) Addressable Style – This FACP is also a control unit that monitors the status of each detection device (smoke sensor, thermal sensor, manual alarm pull station, fire suppression system) and provides the alarm notification. The difference when compared to conventional panels is that addressable systems can provide a much higher level of monitoring and device accuracy. Similar to conventional, these systems will have one or more detection circuits radiating from the FACP to the various devices; however, the system’s memory has stored knowledge about each device, and when one or more of the devices activate, the system recognizes the specific device and then activates the alarm based on the specific events. Addressable systems can be programmed. For example, the activation of a smoke sensor in a space can alert building security to investigate but not sound the general alarm. Then if another device simultaneously activates, this will be viewed as a confirmed fire and the building alarm will operate. Alternatively, the activation of a smoke sensor can put the system in an investigative period and—if not resolved during the period—then sound the general alarm. Addressable systems are customizable so that the alarm is sounded either in the specific zone where the activating sensor is located or in the entire building, and these systems may be integrated into the monitoring capabilities of many security software products. Addressable systems are the current standard for most fire alarm systems.

- Manual Alarm Pull Stations - These are devices that are placed to provide an occupant with the ability to raise the alarm. They are typically located along egress routes to permit alarm while an occupant is escaping the fire.

- Fire Suppression Monitoring - If a fire suppression system is activated, it is crucial that occupants and emergency responders are informed. Fire alarm systems will monitor sprinkler or water mist flow (fire), activation of an extinguishing gas (fire), and system abnormalities that may impact the suppression system’s functionality (e.g. closed valve).

- Alarm Notification - Once a fire has been detected, an alert must be transmitted to the building’s occupants and to emergency responders who can take action to extinguish the fire. Notification includes:

- Audible and Visual – These are the common systems in which occupants are alerted through a combination of an audible device (horn, bell) and a visual device (flashing light or strobe). These signals provide alarm notification without specific directions. More advanced systems replace the audible component with voice speakers that transmit pre-recorded emergency instructions and that can also be used to manually broadcast emergency instructions. Several products can also transmit an array of non-fire emergency alert and notification instructions for events such as weather emergencies and an unauthorized intruder.

- Local – Local alarms are intended to alert the occupants of a room and in the immediate vicinity. A common example is a residential smoke detector.

- Building – Building alarms are transmitted throughout the building to alert all occupants of the fire. A standard building fire alarm system is an example.

- Fire department or central station - These alarms communicate the event to the fire department through direct communication to the fire department or, more commonly, through a 24/7 monitoring company (central station) that can in turn notify the fire department.

In some instances, multiple notification options may be employed. For example, a smoke sensor within a residential bedroom may initially notify the room occupant and a monitoring desk, while a smoke sensor in the corridor or main stairway alarms the full building and notifies the fire department.

- Auxiliary Devices - This is the category of components that provides supplemental actions when the fire alarm activates. Typical examples include door release modules to close a fire door, fan shut down to prevent the climate control system from circulating smoke, and electrical breaker shunts.

- Automatic Detection - One of the factors that contributes significantly to large-loss fires, is when the identification of the developing fire either does not occur or is delayed until after sizable damage has occurred. Therefore, one of the most important roles for a fire detection and alarm system is to identify a developing fire while it is relatively minor and readily extinguished. To accomplish this task there are several automatic fire detection devices that are designed to imitate the human senses of smell, vision, and touch. The selection of a specific device is dependent upon a variety of factors that include the desired point of detection, occupancy capacity, building type, and environmental factors.

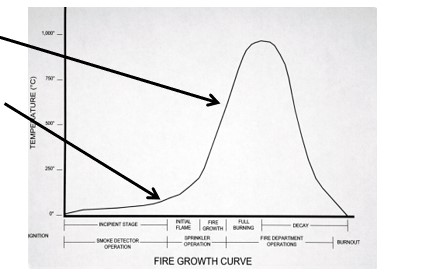

A review of the main phases of fire is helpful to understand where the various fire sensing devices will operate to provide occupant alert and warning, and notification of the fire department.

- Ignition – The point where the interaction between the fuel and ignition source occurs.

- Incipient (Smoldering) – The initial phase that starts relatively small, gaining intensity as time advances.

- Free Burn – The phase where flames, heat, and smoke generation rapidly gain intensity and destructiveness.

- Peak Burning – The point where the fire has reached its maximum level of heat generation. This is the point when the majority of the combustibles within the fire compartment have been effectively destroyed.

- Decay – The gradual diminishing of the fire as fuels are consumed.

- Extinguishment – The final phase when fuels have been consumed so that the fire cannot continue.

In the simplest terms, the earlier that the fire is discovered, the greater the opportunity for safe evacuation and the minimization of damage to the building and its contents. Figure 1 presents a graphic illustration of the typical fire growth phases and, in general, when the various detection devices can operate.

|

Figure 1 - Typical Fire Growth Curve. Courtesy of the author. |

Automatic Detection Technologies

The general types of automatic detection devices are:

- Smoke sensors replicate the sense of smell and can identify an incipient fire. The type of smoke sensing option that is chosen depends on the physical and architectural aspects of the building. Smoke sensors are typically the most-preferred devices; however, there are circumstances where they cannot be used (primarily locations where sub-freezing conditions may occur). Smoke sensors are available in a number of arrangements including single locations (spot type) units, large area projected beam devices, and highly sensitive air-sampling detectors, which are commonly referred to by the brand name VESDA.

- Thermal (heat) sensors replicate the sense of touch and can be used in sub-freezing environments. They are not classified as early warning devices since they do not react until the fire has reached the flaming combustion phase. They are, however, preferred over no detection so that some form of alarm notification is produced. Note that a fire sprinkler is a form of thermal detection.

- Video smoke and flame detection is a relatively new technology that replicates the sense of sight. These devices can function in a variety of environmental conditions, including freezing temperatures. One of the advantages of these devices is their ability to “see” over a very wide area, thereby reducing the number of detectors needed to monitor an area. They are also effective in large, open spaces where it may not be possible to achieve optimal placement of other detector types. One drawback of these units is that if there is inadequate light, such as in a dark room, the smoke-sensing feature does not function.

Factors that impact the selection of a specific detection method include: occupancy, property features, mission criticality, geometric aspects of the structure, fire growth potential, and environmental conditions. In some instances, multiple types of detection technologies may be employed in a given space or property. Some examples of spaces where each detection method may be employed are:

- Smoke – Residential buildings, overnight lodging, offices, egress routes, high value rooms, aesthetically significant spaces, archives, and heated mechanical and electrical equipment rooms.

- Thermal – Non-heated structures and spaces, non-residential storage facilities, and kitchens.

- Video smoke and flame– large open spaces and aesthetically significant areas.

Locations where various detectors are not appropriate include:

- Smoke – Not appropriate for spaces that are subject to freezing, high dust environments, and kitchens.

- Thermal – Not appropriate for residential spaces where occupants will sleep, critical egress routes, high value spaces such as archival vaults, and offices.

- Video smoke and flame – Not appropriate for areas subject to high dust levels, spaces with a large number of partitions, and areas with draperies or tapestries that are subject to wind movement.

Fire Suppression - Overview

Once the fire has been identified and isolated, it must be extinguished. It is generally accepted that the earlier the suppression action is initiated, the lower the resulting damage from both the fire and the firefighting process will be. Fire extinguishment can be undertaken by manual methods (fire extinguishers and fire department operations) or by automatic means, including standard pressure and water mist sprinklers and, in some unique instances, an extinguishing gas. Often both systems may be employed, with the automatic suppression providing the bulk of the effort and manual firefighting completing the extinguishment.

Referring back to the fire growth chart, one can see that when a fire is detected during its incipient stage, it may often be controlled with fire extinguishers and/or relatively minor fire department operations. In practical terms, the incipient stage presents the lowest threat to occupant safety and the smallest risk of damage. However, if the fire reaches the point where flaming combustion occurs (i.e. flame heights exceed approximately 1 meter/3 feet), then the effectiveness of fire extinguishers will rapidly diminish, and more aggressive fire department operations will be necessary. It is after initial flames that the resulting damage from the fire and firefighting will dramatically increase. It is also the transition point at which automatic fire suppression systems will typically activate to stop the fire growth and to diminish the fire’s destructive effects. Figure 2 once again presents the typical fire growth curve and where fire suppression systems can activate.

|

Phase of rapid fire growth and substantial fire impact Transition of fire from a relatively minor fire event to a dangerous and destructive situation, and the point where automatic suppression systems typically activate |

|

Figure 2 – Typical point of automatic fire system response. Courtesy of the author. |

Automatic fire suppression systems use two types of agents to suppress fires – water or gas. For the vast majority of fires, water represents the ideal extinguishing agent, and it is therefore the most widely used automatic suppression method.

- Water systems employ either standard pressure fire sprinklers that are designed to saturate the area where the fire is occurring to prevent ignition of combustibles, or water mists that use a combination of combustibles-wetting and flame/smoke-cooling, both localized to stop fire advancement.

- Gas systems, which may also be referred to as “clean agent” systems, will use either a chemical gas blend or an inerting (oxygen-depriving) blend to stop the fire growth. These are typically used in unique situations where even minimal amounts of water are harmful (e.g. protecting glass negatives) and where the released gas can be confined for a long-enough period of time to complete its extinguishing process. It is crucial that the structure or compartment where gases are used is relatively air tight to maintain gas concentrations and to prevent gas leakage during the extinguishment process, or else reignition becomes possible.

- “Hybrid” systems use inert nitrogen and water mixed at high pressure to produce a cloud that suppresses a fire through cooling and oxygen deprivation. These are used for unique and special applications such as in industrial processes and operations. In cultural heritage settings, they may be appropriate for large open spaces where water supplies are limited, such as a historic shed.

Each of these systems is designed to function early in the fire’s development and, in most instances, to control a fire before the fire department is dispatched, resulting in significantly less damage. Among the potential benefits offered by automatic fire suppression systems are:

- There is an immediate identification of and response to a developing fire. Suppression systems can respond at any time, both when the building is occupied and when the building is vacant and there is no one present to recognize and react to the fire.

- Fire suppression is initiated in advance of a fire department response.

- Enhanced life safety occurs as a result of alerting the building’s occupants through the fire alarm interface, preventing the fire from obstructing egress routes, and preventing fire spread within the building.

- Enhanced fire fighter safety by confining the size of the fire.

- Reduced damage to the building and its contents.

- Design flexibility within building codes that may allow modifications to standard code practices. This can lead to reduced overall building costs and can preserve aesthetically or historically significant features.

- Enhanced security by minimizing the fire size and consequent damage to security controls and features.

- Reduced post-fire down and recovery time and expenditure.

- Possible reduced insurance expenditure since automatically-controlled systems produce lower damage levels than would be typically be encountered in a non-protected building.

Fire Suppression – Water Systems

Water suppression or “sprinkler systems” feature either standard pressure or mist, and both have similar operating principals and components. The exact nature of the components between the two system types can be different since mist systems operate at substantially higher pressures; nonetheless, the basic principles are the same.

Sprinkler systems are essentially a series of water pipes that are supplied by some type of reliable water supply. In most instances this will be the municipal water service, but in rural applications this may be tanks, a pond, or a river. Where water pressure is inadequate to properly supply the system, supplemental pumps may be employed. Frequently, a sprinkler system water supply will be used to supplement fire department hoses.

From the water supply, a network of pipes or tubes delivers the water to the protected spaces. For standard pressure sprinklers, steel is the most common pipe material; however, basic steel piping is subject to mineral deposits and corrosion that results in dirty water discharge when a sprinkler first activates. In some situations, steel may experience a higher corrosion and deterioration rate than other materials. Where cleaner water discharge is necessary or where greater longevity is needed, such as in a historic building application, other pipe materials may be used, including copper tube, CPVC plastic, and stainless steel. A new pipe material known as “Fendium,” which is a polymer enhanced steel, is increasingly available and offers the clean water and longevity benefits of stainless steel at a lower cost.

Along the pipes are independent, heat-activated valves known as sprinkler heads that are responsible for water distribution onto the fire. As the fire gains intensity, the sprinkler’s heat sensing elements are exposed to elevated temperatures (typically in excess of 57–107°C (135–225°F) and begin to deform. After an approximate 30- to 90-second period, the element will fatigue and open the sprinkler’s water seals, discharging water into the fire compartment. Sprinkler heads are made in a wide array of types and styles that are selected by designers to provide optimal water coverage in a variety of building situations. These include “concealed” and custom finished heads to minimize visual impact in aesthetically significant spaces. In most fire situations, two to four sprinklers may simultaneously release to control the fire. However, when a fast-growing fire occurs, such as in a museum “wet collections” laboratory, up to twelve sprinklers may be required. It should be noted that sprinklers do not function unless high temperatures are occurring. They do not operate in the low-temperature smoke conditions that characterize the incipient phase.

Sprinkler systems must include alerting components to send an alarm signal when the system activates, thereby notifying the building’s occupants and summoning the fire department. Systems also should include devices to monitor the system status, such as ensuring valves are in their open position, so that system faults can be identified and corrected before the system fails to properly operate.

There are three basic types of sprinkler systems: wet pipe, dry pipe, and preaction, with each having an applicability that depends on a variety of conditions. These conditions may include one or more of the following: anticipated fire growth rate and potential severity, occupancy and use type, ambient environmental conditions, character defining features and geometry of the building/compartment, and the water sensitivity of the building fabric and contents. In large multifunction facilities, such as a museum or library, two or more system types may be employed.

Wet Pipe

Wet pipe systems are the most common sprinkler system and, as the name implies, they are systems where water is constantly present within the sprinkler piping. When a sprinkler activates, this water is immediately discharged onto the fire.

Wet pipe system advantages include:

- System simplicity and reliability.Wet pipe sprinkler systems have the least number of components and therefore, the smallest number of parts that can malfunction. This produces unexcelled reliability, which is important since sprinklers may be asked to sit in waiting for many years before they are needed. This simplicity is important in facilities where system maintenance is not performed at the optimal frequency.

- Relative low installation and maintenance expenditure.Due to their overall simplicity, wet pipe sprinklers require the least amount of installation time and capital. Maintenance cost savings are also realized since less service time is generally required, compared to other system types.

- Ease of modification.Heritage institutions are often dynamic with respect to exhibition and operation spaces. Wet pipe systems are advantageous because making modifications involves simply shutting down the water supply, draining pipes, and making alterations. Following the work, the system is pressure tested and restored. Additional work for detection and special control equipment is not needed, which saves time and expense.

- Short-term down time following a fire.Wet pipe sprinkler systems require the least amount of effort to restore. In most instances, sprinkler protection is reinstated by replacing the fused sprinklers and turning the water supply back on. Preaction and dry pipe systems require additional effort to reset control equipment.

The main disadvantage of wet pipe systems is that they are not suited for subfreezing environments. There also may be concern in applications where the piping is at risk for severe impact damage, such as in a warehouse setting.

The advantages of wet systems make them highly desirable for use in most heritage applications, and with limited exception, they represent the system of choice for museum, library, and historic building protection.

Dry Pipe

The next system type, a dry pipe sprinkler system, is one in which pipes are filled with pressurized air or nitrogen rather than water. In a heated compartment is a specialized control assembly, referred to as a dry pipe valve, which is held closed by the pressurized air to keep the water out of the pipes. When a fire occurs and a sprinkler opens, the air pressure falls at a rate faster than the make-up compressor can refill it, and the valve opens to allow water flow to the sprinkler.

The main advantage of dry pipe sprinkler systems is their ability to provide automatic protection in spaces where freezing is possible. Typical dry pipe installations include unheated warehouses and attics, outdoor loading docks, and within commercial freezers. Since water is normally not in most of the piping sections, many cultural property stakeholders regard dry pipe sprinklers as advantageous for the protection of collections and other water-sensitive areas based on the perception that a physically-damaged wet pipe system will leak while a dry pipe system will not. This is not true, however, since once the sprinkler opens, water will flow until air pressure is exhausted. (See the System Design section for a discussion of other misconceptions.) With the exception of unheated building spaces and sub-freezing rooms, dry pipe systems do not offer any significant advantages over wet pipe systems, and their use in heritage buildings is generally not recommended.

Dry pipe systems have some disadvantages that must be evaluated before selecting this equipment. These include:

- Increased complexity.Dry pipe systems require additional control equipment and air pressure supply components, which increases system complexity. Without proper maintenance, this equipment may be less reliable than a comparable wet pipe system.

- Higher installation and maintenance costs.The added complexity impacts the overall dry pipe installation cost. This complexity also increases maintenance expenditure, primarily due to added service labor costs.

- Lower design flexibility.There are strict requirements regarding the maximum permitted size (typically 750 gallons) of individual dry pipe systems. These limitations may impact the ability of an owner to make system additions.

- Increased fire response time. Up to 60 seconds may pass from the time a sprinkler opens until water is discharged onto the fire. This delays fire extinguishing actions, which may result in marginally increased content damage.

- Higher pipe corrosion.If dry pipe sprinkler systems are completely drained and dried following a response incident, and if the proper pipe materials and installation techniques are used, then these systems can be trouble free for many years. However, an increasing number of dry pipe systems experience high rates of corrosion and pipe failure, largely due to the use of thin-wall steel piping materials in which the assembly fittings do not allow full drainage. For cultural heritage applications, it is preferred to use a low- or non-corroding pipe such as copper, stainless steel, or Fendium.

Preaction

The third sprinkler system type, preaction, employs the basic concept of a dry pipe system in that water is not normally contained within the pipes. The difference, however, is that water is held from the piping by an electrically operated valve, known as a preaction valve, and the operation of this valve is controlled by independent flame, heat, or smoke detection. Sprinkler operation requires two events: (1) activation of the detector to open the valve and (2) opening of a sprinkler to allow water flow.

The primary advantage of a preaction system is the dual action required for water release, providing an added level of protection against accidental discharge. For this reason, these systems are frequently employed in water sensitive environments such as archival vaults, fine art storage rooms, rare book libraries, and computer centers.

Preaction system disadvantages include:

- Higher installation and maintenance costs.Preaction systems are more complex and have additional components (notably a fire detection system) that increases the overall system cost.

- Modification difficulties. As with dry pipe systems, preaction sprinkler systems have specific size limitations, which may impact future system modifications. In addition, system modifications must incorporate changes to the fire detection and control system to ensure proper operation.

- Potential reduction in reliability.The higher level of complexity associated with preaction systems creates an increased chance that something may not work when needed, and subsequently, a higher level of maintenance is essential to ensure reliability. If the facility's management installs preaction sprinkler protection, they must remain committed to installing the highest quality equipment and to maintaining these systems as required.

Provided the application is appropriate, preaction systems have a place in heritage buildings, especially in water sensitive spaces.

A variation of the preaction system is the on/off sprinkler system, also referred to as a “Firecycle” system. These systems are essentially preaction-type systems with restoring thermal sensors located within the protected space. Similar to a standard preaction arrangement, both the thermal sensor and the sprinkler head must operate to permit water flow. The key difference is that as the fire is suppressed and room temperatures diminish, the thermal sensor will cool and shut off the flow of water through the system controller. If, however, the fire resumes and temperatures once again rise, the sensor will go back into alarm mode, and the water flow will resume. This cycle may occur repeatedly until the fire is completely extinguished or the fire department shuts of the system after having manually extinguished the fire. Firecycle systems are well suited for applications where water application must be minimized and/or water supplies are limited, as encountered in rural areas.

Another preaction variation is the deluge sprinkler system, which is basically a preaction system using open sprinklers. Operation of the fire detection system releases a deluge valve, which in turn produces immediate water flow through all sprinklers in a given area. Though rarely used for cultural heritage applications, they can be appropriate on the building exterior to prevent an exterior fire from entering the structure. Typical use examples include urban settings with close proximity neighboring structures and in areas that are subject to wild-land fires.

Water Mist

This variation on a sprinkler system uses fine water droplets, or “mists,” to automatically control fires. Mist technology was originally developed for offshore uses such as ships and oil drilling platforms. They are the de facto fire protection technology for most modern cruise ships and ocean liners and have a solid track record dealing with maritime fire incidents. Mist systems are also used for numerous land-based applications including in many museums and historic and iconic buildings. Their use has been widest in Europe, where many of these systems were developed and extensively tested. In North America, there are examples of successful mist installations, and their use continues to expand.

Mist systems can be selected and installed in a wet pipe, dry pipe, or preaction arrangement similar to standard sprinklers. They can also be employed with an array of open nozzles to create a barrier that can cool window glazing and structural elements or limit smoke spread, Mist systems discharge limited water quantities at higher pressures than sprinkler systems (at pressures that can range from approximately 200 to 1,000 psi (13.6-68 bar)). This results in the production of extremely fine water droplets that have a much greater surface area than those from conventional sprinklers. This added surface area increases the fire-fighting efficiency of the water and results in a faster fire control with substantially less water. In many situations, mist controlled fires will use approximately 10-25% of the water associated with regular sprinklers. This leads to significantly lower rates of water saturation on building fabric and contents. Since mist systems operate at higher pressure, conventional steel pipe materials are not allowed, resulting in the use of longer-lasting materials such as stainless steel that also result in cleaner water discharge.

The main disadvantages of mist systems is the higher cost associated with their purchase and installation and the higher labor cost that is needed in some instances to fit these systems. In most regions there are few certified installation contractors, so installation expertise may need to be brought in from a distance. Mist systems may also have higher annual maintenance costs. Where appropriate, however, water mist sprinklers can be an excellent protection technology.

System Design

Several common misconceptions about sprinkler systems exist and consequently, cultural property stakeholders may be reluctant to provide this protection, especially for collections storage and other water-sensitive spaces. Typical misunderstandings include:

- When one sprinkler operates, all will activate.With the exception of deluge systems (discussed later in this leaflet), only those sprinklers in direct contact with the fire's heat will react. Statistically, approximately 61% of all sprinkler-controlled fires are stopped by two or fewer sprinklers.

- Sprinklers operate when exposed to smoke.Sprinklers function following thermal impact against their sensing elements. The presence of smoke alone will not cause activation without high heat.

- Sprinkler systems are prone to leakage or inadvertent operation.Insurance statistics indicate a failure rate of approximately 1 head failure per 16,000,000 sprinklers installed per year. Sprinkler components and systems are among the most-tested systems in an average building. Failure of a properly-installed and -maintained system is highly unlikely. When failures do occur, they are usually the result of improper design, installation, or maintenance. Therefore, to avoid problems, an institution should carefully select the contractors who will be responsible for the installation and should ensure that staff and vendors are committed to proper system maintenance.

- Sprinkler activation will cause excessive water damage to contents and structure.Water damage will occur when a sprinkler activates. This issue becomes relative, however, when compared to alternative suppression methods. The typical sprinkler will discharge approximately 25 gallons per minute (95 liters per minute) while the typical fire department hose delivers 100–250 gpm (378-945 lpm). Sprinklers are significantly less damaging than hoses. Since sprinklers usually operate before the fire becomes large, the overall water quantity required for control is lower than in situations where the fire continues to increase until firefighters arrive. A point to consider is that the water damage from sprinkler systems is usually repairable/restorable while burned-out structures and contents are usually not.

- Sprinkler systems look bad and will harm the building's appearance.This concern typically originates with someone who has observed a less-than-ideal-appearing system, and admittedly, there are some poorly-designed systems out there. That said, sprinkler systems can be designed and installed with almost no aesthetic impact.

To ensure proper design, the institution and design team should take an active role in the selection of visible components. Sprinkler piping should either be concealed or placed in a decorative arrangement to minimize visual impact. Only sprinklers with high quality finishes should be used. Often sprinkler manufacturers will use customer provided paints to match finish colors, while maintaining the sprinkler's listing. The selected sprinkler contractor must understand the role of aesthetics.

To help ensure overall success, the sprinkler system designer should understand the institution's protection objectives, operations, and fire risks. This individual should be knowledgeable about system requirements and willing to implement unique, thought-out solutions for areas where aesthetic or operational concerns exist. The designer should be experienced in the design of systems in architecturally sensitive applications.

Ideally, the sprinkler contractor should be experienced working in heritage applications or, alternatively, in water-sensitive applications such as telecommunications, pharmaceuticals, clean rooms, or high-tech manufacturing.

The selected sprinkler components should be provided by a reputable manufacturer that is also experienced in water-sensitive applications. The cost differential between average- and high-quality components is minimal. The long-term benefit, however, is substantial, and considering the value of a facility and its contents, the extra investment is worthwhile.

With proper attention to selection, design, and maintenance, sprinkler systems will serve the institution without adverse impact. If the institution or design team does not possess the experience to ensure the system is proper, a fire protection engineer experienced in heritage applications should be consulted.

Fire Suppression – Gas / Clean agent

While fire sprinkler systems are usually the most effective choice for automatic fire control, there are some situations where the water sensitivity of a building feature or unique artifact may be such that any amount of water will be destructive. For these unique situations, there are several fire extinguishing gases, also referred to as “clean agent” systems. A clean agent system consists of the following components:

- Control panel. The control panel is the device that monitors the status of the discharge-initiating detectors, raises the alarm to notify occupants and the fire department, and then activates the extinguishing gas discharge. Control panels may be dedicated for the system or for a part of the main building fire alarm system.

- Detectors. A series of automatic detectors (smoke type) will be within the protected space to identify the fire during its incipient phase. There will usually be a manual releasing station that allows someone to activate the gas discharge if they discover the fire before the smoke sensors operate.

- Notification devices. Alarm notification devices, usually sounding horns and flashing lights, will be both inside and outside a room to indicate that the system is about to discharge or has discharged. These alarms are intended to alert the occupants of the room to evacuate before the gas releases and also to alert those outside of the room to stay out while the gas is suppressing the fire.

- Gas and storage cylinders. The specific gas agent is stored within one or more dedicated, pressurized cylinders. The quantity of gas that is stored is determined by several factors including the room geometry and the specific materials that are being protected.

- System piping and nozzles. From the gas cylinders is a network of pipes with a series of open nozzles that are specifically placed to optimally discharge the gas throughout the protected space.

- Room enclosure. While not technically a part of the gas extinguishing system, the room enclosure – walls, ceilings, floors, and associated openings such as doors and vents – are crucial to the system’s success. Gas systems have a limited discharge that is based on the quantity of agent within the cylinders. This quantity is calculated to provide a prescribed gas-to-air concentration level (e.g. 5-10%), and if the gas does not remain within the protected compartment, then the extinguishing success will be compromised. As such, the room must be properly constructed and maintained to provide a relatively tight enclosure.

The key advantage of a gas suppression system is that it extinguishes the fire without water. This is important where the building features or contents are highly water sensitive and can be equally damaged by water as by fire.

The main disadvantages of gas systems are that they are limited duration systems and only applicable for unique and special applications. They are rarely recommended for full building protection. Depending on the specific gas, the discharge can be forceful enough that physical damage to unsecured contents may result. In some instances, depending on the composition of the room contents, discharge may result in chemical damage. It is advisable to obtain the specific chemical composition of the gas used and to seek conservation expertise regarding how the gas may interact with specific items. (Unfortunately, due to the varied nature of heritage items, there is not a single source of information on this subject.) Finally, some of these gases are under increased scrutiny for their potential contribution to greenhouse gases, which should be considered prior to selecting a specific gas so that there can be assurance that the gas will be available in the future.

Fire Suppression – Hybrid Systems

A variation of gas systems is the hybrid system, which is similar in detection and control but—rather than a pure gas—it utilizes water and nitrogen to create an exceptionally fine water vapor. Like gas systems, these are limited duration systems, but they are more effective than gas in situations where the compartment is not completely tight. Hybrid systems elevate the room humidity, which is a factor to be considered when selecting these systems, but otherwise, they are very similar to gas suppression technologies. A key advantage is that they are not classified as contributing to greenhouse gases, and therefore are not at risk of being discontinued.

As with the various water-based systems, extinguishing gases and hybrid systems have their respective place for specialized hazard protection and can be very successful when properly selected and used.

Conclusion

In summary, there are many options for identifying a suppressing a fire, and there is not a standard solution to all fire protection situations. The key is to obtain professional and unbiased assistance so that the organization’s specific fire protection goals and objectives can be established and then the appropriate technologies selected. It is crucial that the institution’s stakeholders are active participants in the selection process and ensure that the needs of the institution are properly addressed. Once the appropriate technologies and systems components have been identified, the same level of professional assistance should be employed to make sure that the system is carefully designed, constructed, and maintained.

Resources

Codes

National Fire Protection Association (NFPA) #909 Code for the Protection of Cultural Resource Properties - Museums, Libraries, and Places of Worship, www.nfpa.org.

NFPA #914 Code for the Protection of Historic Structures, www.nfpa.org.

Organizations

The following organizations are available to assist with selection of fire suppression systems:

National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02169. Telephone: (617) 770-3000. http://www.nfpa.org.

Society of Fire Protection Engineers (SFPE): 9711 Washingtonian Boulevard, Suite 380, Gaithersburg, MD 20878. Telephone: 301-718-2910 http://www.sfpe.org.

Acknowledgements

Written by Nick Artim, P.E. (fire protection). This is an updated version of Artim’s 1999 NEDCC Preservation Leaflet on the same topic.

Attribution-NonCommercial-NoDerivs

CC BY-NC-ND