3.1 History| 3.2 Materials and Preservation Risks| 3.3 Carrier Types and Preservation Problems| 3.4 Reproduction Methods| 3.5 Best Practices for Storage and Handling

Section 3: Magnetic Media

3.1 History

Tape

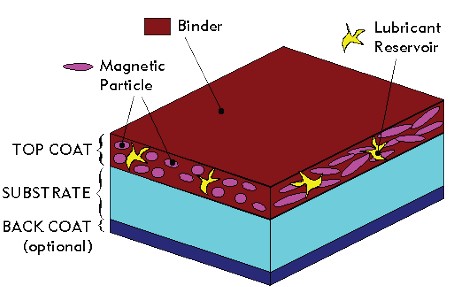

| FIGURE 1.7 Cross section of Magnetic Tape. Credit: the Commission on Preservation and access and the National Media Laboratory, Magnetic Tape Storage and Handling: A Guide for Libraries and Archives, https://www.clir.org/pubs/reports/pub54/2what_wrong. |

|

|

|

The ability to record audio on magnetic tape in a consistent way first came on the scene in Germany in the late 1920s. It wasn’t until the late-1930s that the tapes could be mass produced and the playback devices were stable enough for general use. The quality of recordings began quite poor, but had improved dramatically by the early 1940s. However, it wasn’t until after WWII that magnetic tape recorders made it to the United States. Singer and actor Bing Crosby heavily invested in magnetic tape technologies and helped to bring the medium to broadcast radio in the United States. Magnetic tape recordings were a huge improvement over the transcription discs that had previously been used in broadcast radio: they were of better quality and easier to edit.

Magnetic tape recording is built on the same basic concepts on which the telephone was created: mechanical sound waves are converted into electrical current, transported through cables, then converted back to sound waves. Magnetic tape recordings add an additional step - a magnetizing coil is used to record the signal. In the early days of magnetic tape recording, the signal was recorded onto paper coated iron oxide; the paper was later replaced with the acetate and polyester base with which we are all more familiar.

For all tape there is one side that contains the magnetic particles on which information is recorded. These magnetic particles are adhered either through use of a binder system or the metal evaporated tape process. The opposite side of the tape will either be the bare side of the substrate or a back coat that is added on.

Soon after the introduction of magnetic tape audio recordings to the United States, the same principle was applied to video. Video signals are similar to audio signals, but have a much higher bandwidth, meaning a lot more information must be recorded in order to properly reproduce the signal. This hurdle was overcome with the invention of the spinning recording head that allowed for much more information to be recorded and read. It wasn’t until much later that further advancements and improvements were made so that the medium became compact and easy enough to handle that video was able to enter the home market.

Wire

Magnetic wire recordings actually pre-date magnetic tape recordings. They were first invented in 1898 and were meant to record dictation. Wire recording did not really catch on as a major format until the mid-1940s when technical improvements made it both better quality and more affordable. It began to be marketed not only for office use, but also for home recording. By the mid-1950s, however, magnetic tape recorders had caught up in quality and price and quickly surpassed the wire recorder in use.

Again, the recording method recalls the principles of the telephone. The electrical audio signal magnetizes the wire as it passes quickly over the recording head. The magnetized signal corresponds to the intensity and polarity of the original signal. During playback, the wire is run over the same head, but since there is no signal being supplied during playback, the changing magnetic field present on the wire reproduces the original signal.

3.2 Materials and Preservation Risks

| FIGURE 1.8 A reel of acetate tape will appear translucent when held sideways between your eye and a light. Credit: AVP |

|

|

The base materials for tape fall into one of four basic categories. These are acetate, polyester, PVC, and paper. Acetate, PVC, and paper will only be found on open reel audio. All audiotape housed in cassettes and all videotape is polyester based.

Paper-based tape is notable in look and feel and is somewhat rare to come across. The associated handling follows basic common sense regarding the sensitivities of paper-based materials and the possibility of tearing. Acetate can be identified by holding a reel of tape sideways between your eye and a light. If it is translucent then you are holding an acetate tape. If it is opaque then it is either polyester or PVC.3

3.3 Carrier Types and Preservation Problems

| FIGURE 1.9 A tape with sticky shed syndrome has left this sticky residue on the playback machine. Credit AVP |

|

|

|

FIGURE 1.10 Diagram of a Tape Reel. Credit: the Commission on Preservation and Access and the National Media Laboratory, Magnetic Tape Storage and Handling: A Guide for Libraries and Archives, https://www.clir.org/pubs/reports/pub54/2what_wrong/. |

|

|

|

FIGURE 1.11 Unwound magnetic tape. Credit: AVP |

|

|

Tape, whether audio or video, analog or digital, comes in two basic forms: open reel and cassette. Open reel tape has tape wound around a hub with flanges on the sides, with tape ranging in width from ¼” to 2”. Audiotape is sometimes stored on a hub with no flanges attached. This is referred to as a “pancake” and requires special attention because it is particularly prone to coming unwound.

Cassettes come in a range of sizes, typically housing tape widths from ⅛” to ¾”. There are also cartridge formats that are more blockish in appearance, but the construction is more or less the same.

An issue pertaining primarily to audio open reel is that of degrading splices. This pertains primarily to audio open reel because it is rare for cassette based formats to have splices and uncommon for video open reel to have splices. If there are splices in video open reel they tend to be few in number. Audio open reel tapes on the other hand have been known to have anywhere from none to hundreds of splices. Issues with degrading splices can range from splicing tape that simply dries up and breaks to extruding adhesive, causing multiple adjacent layers to stick together.

Wire recordings are specific to audio and typically consist of stainless-steel wire that is between .004 and .006 inches in diameter wrapped around a spool. Spools of wire are commonly 3” in diameter and .75” wide, although these dimensions can vary depending on when and for which application the wire was made.

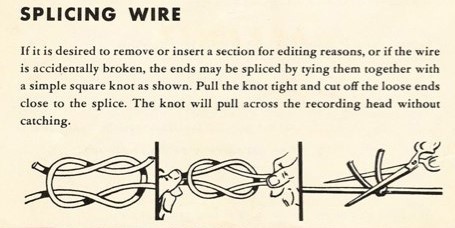

The wire itself does not have degradation mechanisms, as it is made of steel. The biggest risk factor to the physical state of wire recordings is becoming tangled in transport, which can lead to breakage or the need to cut out sections in order to resolve the tangle. For this reason, it is important to make sure wire recordings are played back and wound on a transport that is known to be in good working order. Adhesives from splicing are not a concern, because the process for wire recordings involves tying a square knot.

Improper storage, care, and handling practices may result in the following tape and/or wire issues, impairing reproduction:|

FIGURES 1.12 & 1.13 |

|

|

|

- Deposits of matter such as dirt, dust, hair, and even fingerprints that create separation between the tape or wire and the head.

- Edge damage and tape deformation caused by mishandling, degradation, poor storage, or a bad transport. Even when slight, this type of damage can cause variation in the tape’s contact with the head, resulting in the creation of artifacts.

- Broken or poorly repaired splices on both tape and wire.

- Adhesive extruding from splices and adhering to adjacent layers of tape.

- Binder system failure, including sticky shed syndrome, causing poor cohesion and high friction during transport of tape.

- A broken cassette or reel.

- Tangled wire.

- Magnetic particles that were originally recorded to tape, but scratched off or otherwise removed.

- Magnetic particles that were originally recorded, but were exposed to a magnetic force that changed their magnetic state on both tape and wire.

3.4 Reproduction Methods

The reproduction method for magnetic tape and wire is electromagnetic, meaning that the tape or wire reproducer head in the playback machine converts the magnetic energy stored on the tape or wire to electrons or voltage which is ultimately converted back to light and sound. It is critical that there be good and precise contact between the tape/wire and the playback head in order for the magnetic energy to be properly read and converted to electrons. It is also critical that the magnetic particles containing the recorded information remain in place and do not have their magnetic state altered.

3.5 Best Practices for Storage and Handling

Tape

Environment

- Store at temperatures between 32 and 61 degrees Fahrenheit,4 with a relative humidity (RH) between 30%-50%. Temperatures should not fluctuate more than ±3 degrees within a 24 hour period. RH should not fluctuate more than ±5% within a 24 hour period.5

- Keep away from magnets, items containing magnets, and items generating magnetic force.

Housing

- Store on edge standing vertically.

- Containers should support reels by the hub.

- Place in housings that protect from external elements.

- Open reel tape should be stored tails out.

- The end of an open reel tape should be taped down, either to itself or the reel flange, using “hold down” tape intended for this purpose.

- Use only splicing tape for splices; use only hold down tape to secure tape ends.

- Wind cassettes all the way to one end.

- Avoid excessive pressure (enough to press a reel flange or cassette housing against the tape) on any side of the container or housing.

Handling

- Wear non-abrasive, non-shedding gloves if touching areas of the tape containing recorded information.

Wire

Environment

- Store at temperatures between 33 and 54 degrees Fahrenheit, with RH between 30%-50%. Temperatures should not fluctuate more than ±3 degrees within a 24 hour period. RH should not fluctuate more than ±5% within a 24 hour period.

- Keep away from magnets, items containing magnets, and items generating magnetic force.

Housing

- Place in housings that protect from external elements.

Handling

- Do not touch areas of the wire containing recorded information without using non-abrasive, non-shedding gloves.

- Tie down end to keep it from coming loose and unwinding.

- Use only a square knot for splices.

| FIGURES 1.14 & 1.15 Store magnetic tape on edge, standing vertically. Credit: AVP |

||

|

|

|

|

FIGURE 1.16

|

SPLICING WIREIf it is desired to remove or insert a section for editing reasons, or if the wire is accidentally broken, the ends may be spliced by tying them together with a simple square knot as shown. Pull the knot tight and cut off the loose ends close to the splice. The knot will pull across the recording head without catching. |

|